Spectrotek Services  Rife Plasma System Components

Rife Plasma System Components

Current as of

03 December 2017

Side Electrode Wires for the SSQ-BAT Plasma

Tube

By adding a pair of side

electrode wires, the initial firing voltage of the SSQ-BAT is reduced.

If you are using an SSQ-BAT, this modification is

strongly suggested to help prevent amplifier damage.

This

change in electrode configuration helps to protect the PA1, PA2, PA3,

or SPA4 amplifier from excessive tank circuit voltage that is generated

when the amplifier is producing RF output power but the plasma tube has

failed to light immediately. This may happen when using high modulation

frequencies or when the duty cycle is short. A short duty cycle may be

caused by a combination of simultaneously running modulation

frequencies that combine to produce very short output pulses. When this

happens, the plasma tube may fail to light during part or all

of

the RF output pulse from the amplifier. This failure to of the tube to

light may cause amplifier failure, with the destruction of the

STW20NK50Z MOSFET in the amplifier.

The

reason for this failure to light immediately is due to the lack of

ionized gas present when the tube is not turned on. Because it requires

some milliseconds for all of the ionized gas to in the tube recombine

after the power to the tube is turned off, the tube will normally light

properly once it has gone into conduction, as long as the OFF time is

substantially less than the ion recombination time. However, when the

tube is first turned on, or if the OFF time between modulation pulses

is long enough, the number of available ions in the tube will have

fallen so low that the tube becomes non-conducting. As a result, it

will require a much greater applied RF voltage across the tube

electrodes to light the tube for the first modulation pulse than it

will for subsequent pulses.

Should

a series of very short pulses be applied to the tube when it has not

been conducting previously, it is quite possible that the tube may fail

to light at all during the series of short pulses. This failure to

light will create very high voltages across the amplifier, and may

cause MOSFET failure. These failures can be extremely difficult to

trace, since they tend be intermittent and random. A system

that

has been functioning perfectly for an extended period

of time may suddenly experience one or more MOSFET failures within a

short interval. The addition of the side electrode wires as described

here will virtually eliminate this problem.

No adjustment or tuning of the

LC31 coupler is required in order to add these side electrode wires.

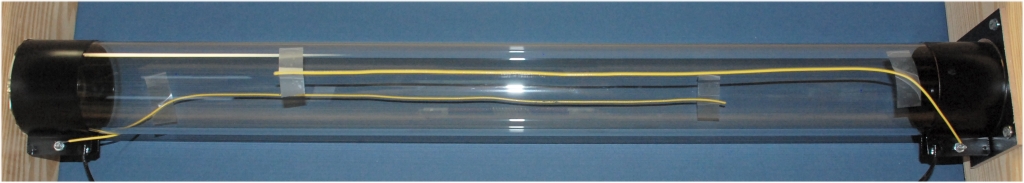

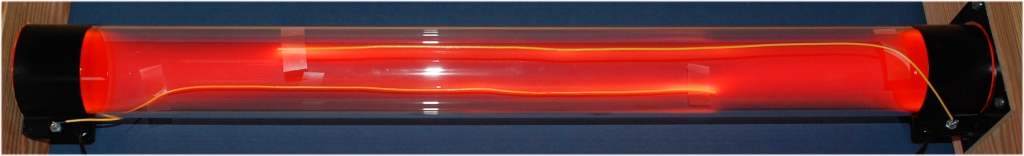

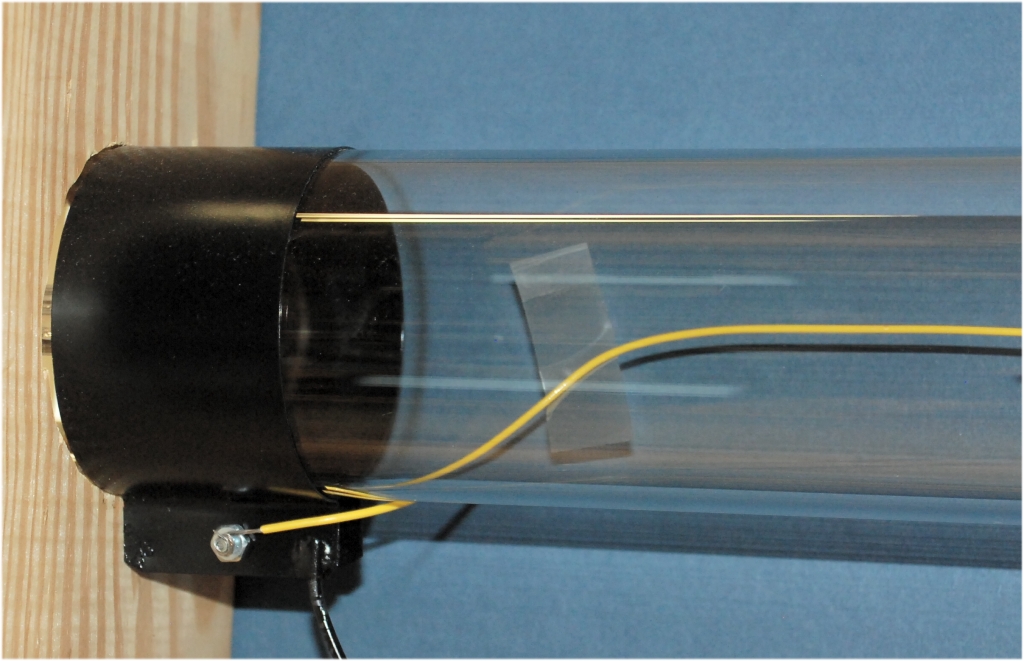

SSQ-BAT

with side electrode wires temporarily installed with adhesive tape for

testing.

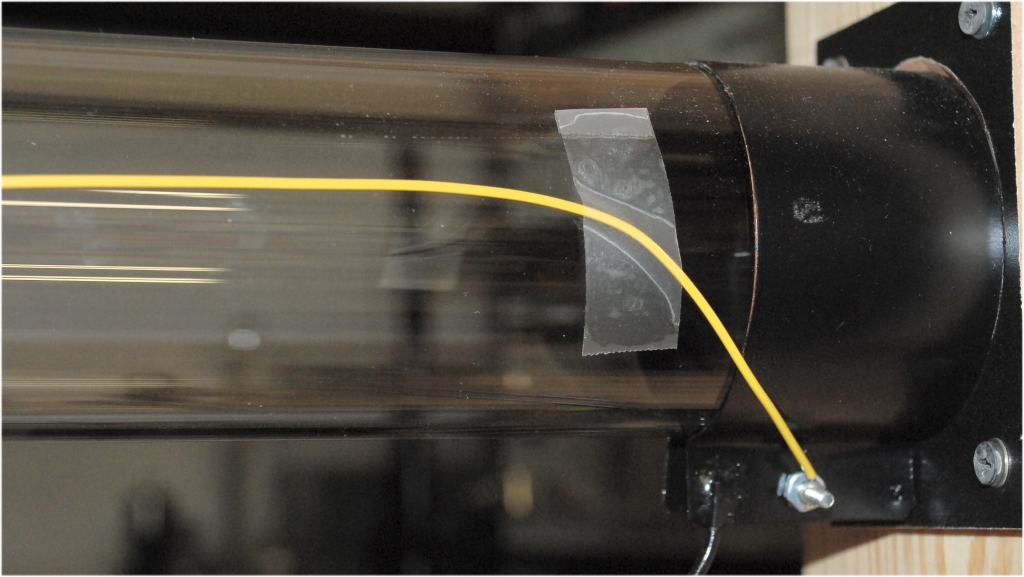

SSQ-BAT

with side electrode wires temporarily installed with adhesive tape for

testing.

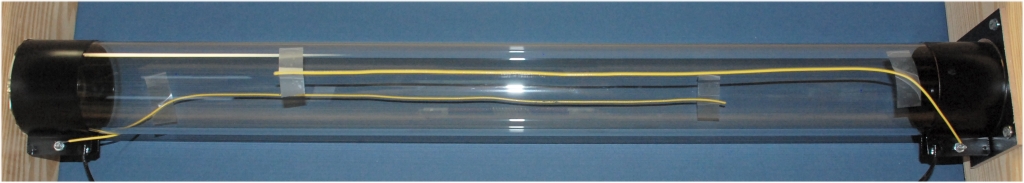

SSQ-BAT

with side electrode wires permanently mounted in place using Silicone

adhesive.

SSQ-BAT

with side electrode wires permanently mounted in place using Silicone

adhesive.

Plastic

tape was used to hold the side wires in place during testing. For these

tests, the bare end of the wires were simply twisted around the collar

electrode mounting screws. Because of the low current flowing in the

side wires, this simple connection method was satisfactory for

testing.

The wires should be insulated. Teflon insulation is

ideal from the standpoint of heat resistance, but any type of

heat

resistant insulation is OK. Bare wires should not be used because the

RF voltage on the wires may become high enough where the wires touch

the tube to cause localized overheating of the tube wall. This may

cause the glass to crack at that point, ruining the tube. The

insulation on the wire will space the wire far enough from the tube

wall to reduce the electrical and heat stress enough to prevent tube

damage. The wire used here is AWG 22, but any wire from AWG 24 to AWG

10 should work as well.

The wires should run on opposite sides

of the tube, directly across from each other. It does not matter where

they are placed, side, top, bottom, or wherever, just place them across

the tube from each other. The wires should extend about three-quarters

of the distance from one electrode to the other.

For these

photos, the wire was held in place with plastic tape. If you have tape

which will tolerate 100° C temperature without melting or loosening,

then using tape will work OK. On my tube, I used Silicone seal

adhesive, which will withstand high temperatures. I used several strips

of tape to hold the wires in place against the tube, and then applied

four blobs of the adhesive to hold the wire against the tube. The tape

was removed 24 hours later after the adhesive had hardened. Do NOT use

an adhesive which is not flexible when it has hardened. A non-flexible

adhesive can cause the glass of the tube wall to spall when it gets

hot. This may result in a shattered tube.

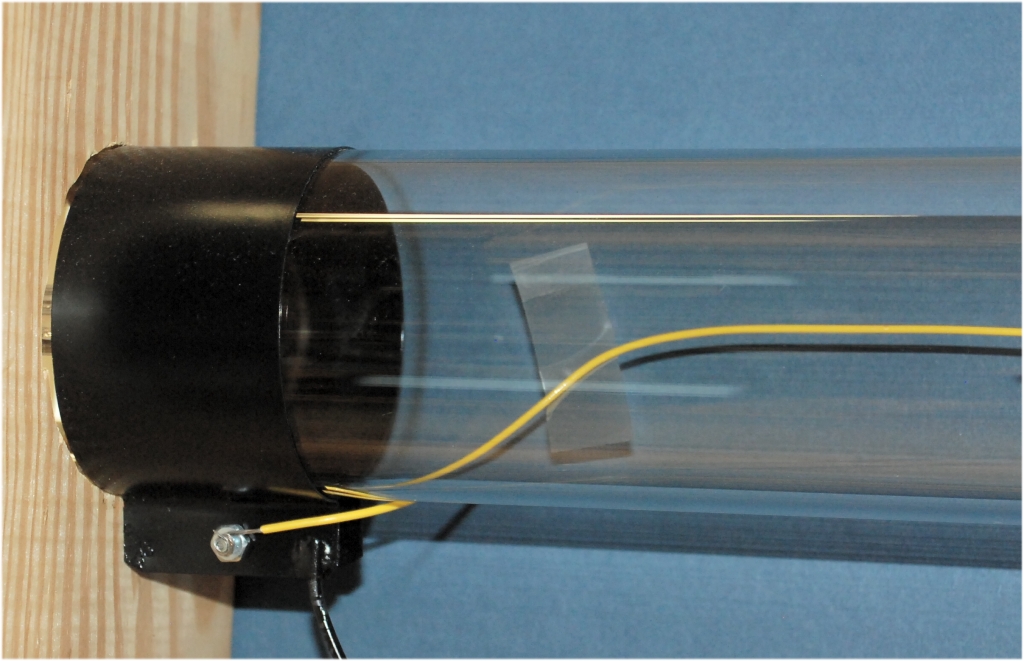

Orientation

of the side electrode wire on the left side of the plasma tube.

Orientation

of the side electrode wire on the left side of the plasma tube.

This

wire is connected to the collar electrode mounting screw on the

opposite side of the tube from the side wire. It does not matter which

side of the collar electrode the side wire is connected to. In this

case, for testing, it was easier to bring the wire across the bottom of

the SSQ-BAT tube to reach the long end of the mounting screw.

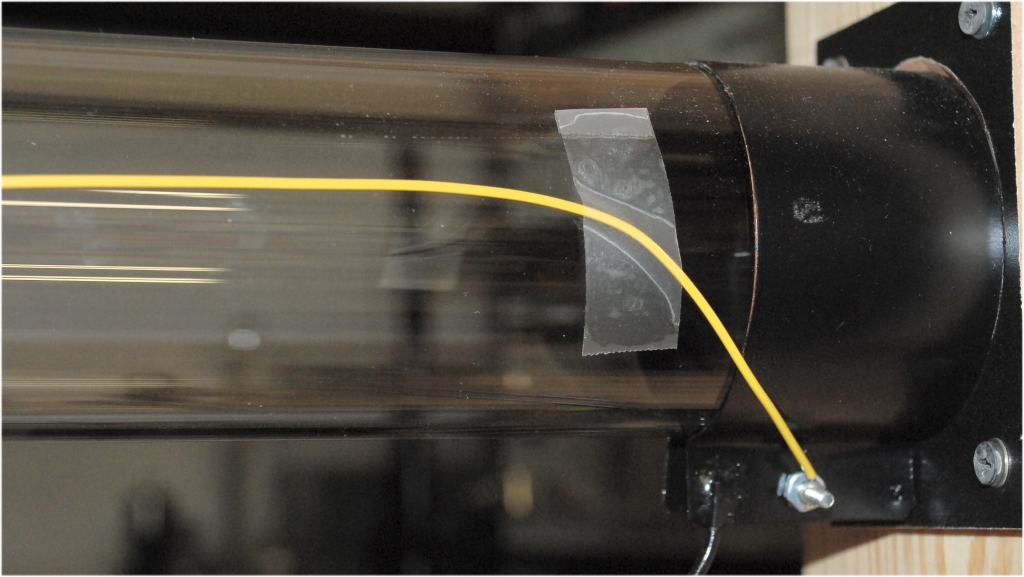

Orientation

of the side electrode wire on the right side of the SSQ-BAT plasma tube.

Orientation

of the side electrode wire on the right side of the SSQ-BAT plasma tube.

In

this case, the side wire simply goes directly from the collar electrode

mounting screw up and over to the side of the SSQ-BAT. Reversing the

mounting screw of the left side collar electrode would have allowed

connecting the side wire seen in the previous photo to connect to the

electrode in the same manner as this wire.

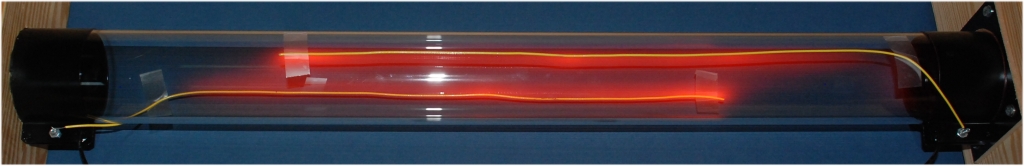

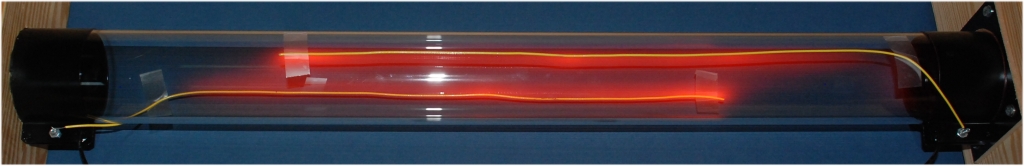

SSQ-BAT

running with an amplifier voltage of 19 volts. Power is about 5 watts

peak power.

SSQ-BAT

running with an amplifier voltage of 19 volts. Power is about 5 watts

peak power.

At

this low power level, there is not enough available energy to light the

tube from one collar electrode to the other. In this condition, the

tube does not provide the proper load to the LC31 coupler and the

amplifier. Without the side wires, the tube would not light at

all, and the RF voltage from the LC31 coupler and in the amplifier

output tank circuit would increase, possibly rising high enough to

cause the STW20NK50Z MOSFET to fail.With the side wired

present on the SSQ-BAT, the voltage that is produced by

the LC31 coupler is high enough to ionize the gas between the side

electrode wires. This loads the amplifier enough to prevent damage,

even though the tube is not yet in full conduction.

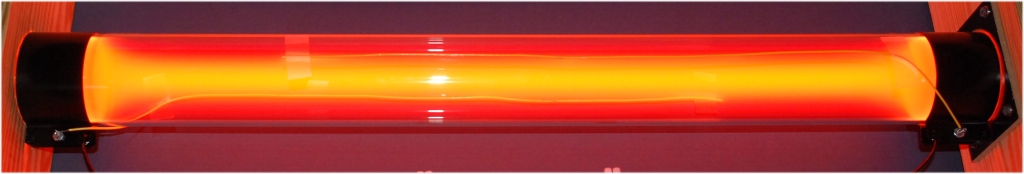

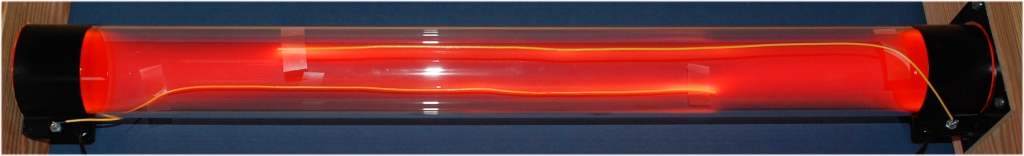

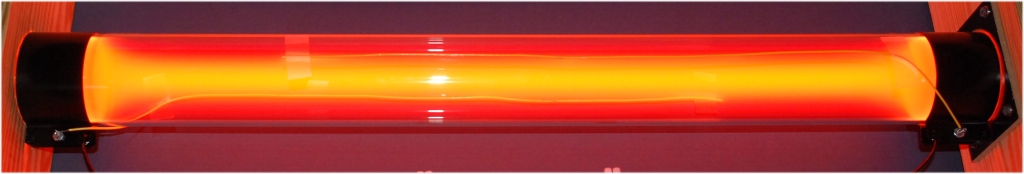

SSQ-BAT

running with an amplifier voltage of 38 volts. Power is about 80 watts

peak power.

SSQ-BAT

running with an amplifier voltage of 38 volts. Power is about 80 watts

peak power.

At

this power level, the tube is in almost full conduction. The glow

discharge is now connecting to both collar electrodes and passing down

the side of the tube. The amplifier loading is correct, and the

electrical waveform is correct. Before the addition of the side wire

electrodes, the tube would not exhibit proper operation until at least

75 volts was applied to the amplifier. The addition of the side

electrode wires has made a considerable improvement in the electrical

performance of the SSQ-BAT plasma tube.

SSQ-BAT

running at an amplifier voltage of 114 volts. Power is about 250 watts

peak power.

SSQ-BAT

running at an amplifier voltage of 114 volts. Power is about 250 watts

peak power.

Here

the tube is well into full conduction and working properly. The

discharge column has tightened up and now passes down the central

region of the tube. There is little interaction with the side electrode

wires at this power level.

This

web site and all contents including

pictures, text and diagrams is

Copyright © 2012 - 2018 by Ralph M Hartwell.

Rife Plasma System Components

Rife Plasma System Components Rife Plasma System Components

Rife Plasma System Components